Specific causes and solutions

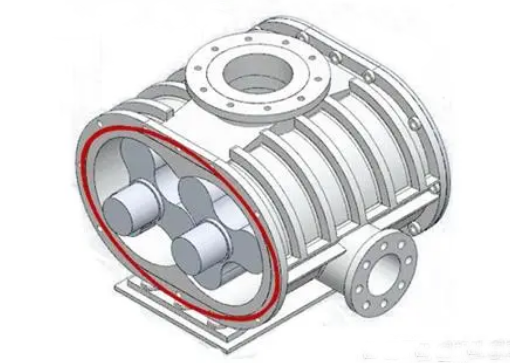

Friction between the rotor and the shell or rotor is a common fault of Roots fan, if this fault occurs in operation, it will be accompanied by serious vibration and noise. Roots fan after a long period of downtime, often appear rotor jamming, disk does not move the phenomenon of the car. The main causes of failure are summarized in six categories.

1, process reasons

As the process medium contains a large amount of dust and water vapor, when the medium through the fan will have dust adsorbed in the shell and rotor surface, so that the gap between the shell and the rotor to reduce. The adsorbed dust will become hard or even plasticized when squeezed, resulting in friction or even jamming of the rotor, especially after the shutdown and start again, often disk does not move the car.

Solution: Stop as little as possible, after stopping regularly disk car, you can find out the fault in advance, to avoid the impact of production when driving. Regularly check the inlet filter and clean the filter; regularly open the air release valve to release the water vapor condensation.

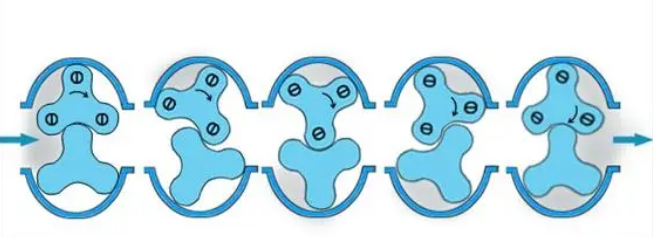

2, the rotor lobe, closed lobe clearance is not appropriate

Rotor lobe, lobe gap is not suitable, running lobe, lobe gap changes. The two rotors will collide in low-speed rotation, resulting in friction between the rotors or even jamming. If this fault occurs during operation, it will cause collision between two rotors or between the rotor and the shell, emitting strong impact sound; the vibration becomes bigger, and even cause foundation vibration; at the same time, the temperature of the friction part rises rapidly, and even the phenomenon of the casing is hot and red.

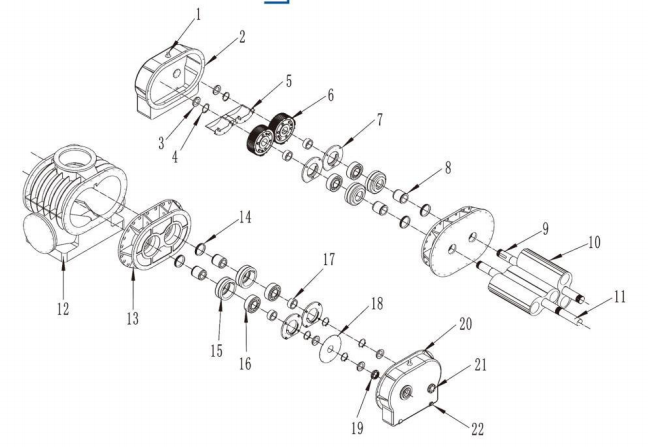

Solution: Check the value of rotor parting and closing lobe clearance with a plug ruler, so that it is within the standard range. Check the back cap and bolts for adjusting the clearance to ensure its integrity. Requirements: split lobe clearance accounted for 1/3 of the total clearance, but not less than 0.15mm; combined lobe clearance accounted for 2/3 of the total clearance, and to be greater than the gear side clearance 1.5 times. Rotor split, combined lobe clearance is shown in Figure 2. combined lobe for the active rotor engagement face passive rotor has a tendency to approach; split lobe for the active rotor engagement face passive rotor has a tendency to move away. If the rotor lobe, lobe gap is not appropriate, you can adjust the tooth sleeve and hub or gear and shaft circumferential relative angle.

Adjustment of rotor lobe, lobe is a key part of the Roots fan overhaul, which directly determines the quality of the overhaul. Different types of Roots fan, there are different forms of adjustment. Shaft and gear for cone-type keyless connection, generally through the adjustment of shaft and gear circumferential relative position adjustment of the split lobe clearance; shaft and gear for the key connection, generally through the adjustment of the slave gear and the hub of the relative position adjustment. Fan normal operation process, with the gear wear, the gap will change, which tends to reduce the gap between the blade, tend to increase the gap between the blade. In adjusting the working clearance of the two impellers, should be in advance of the combined lobe clearance properly adjusted, the general combined lobe clearance is 2 times the split lobe clearance.

3、Bearing damage

Poor operating conditions of the fan, oil seal damage, assembly clearance exceeds the standard, etc. will lead to bearing damage, and bearing damage will cause the temperature to rise, the temperature of the bearing seat will also increase, and in serious cases, the bearing seat will be deformed. Especially when the inner and outer rings of the bearing hold, the bearing housing and the side cover plate are subjected to large additional force, and the temperature will be high, the bearing housing and the side cover plate are not uniformly heated, which will cause the side cover plate to be deformed and cracked in serious cases.

Shaft diameter wear, so that the shaft and bearing inner ring clearance is too large, bearing seat wear so that the bearing seat and bearing outer ring clearance is too large, will cause rotor jamming or friction. Especially the belt connected fan, the active shaft due to the role of the belt tension, resulting in bearing seat one-way force is larger, easy to belt side of the active shaft bearing seat one-sided wear.

Solution: Replace the bearing and check whether the side cover plate is deformed with cracks. If the deformation is not serious, the high point can be polished; if the deformation is serious, the side cover plate can be replaced; if there is a crack, it can be patch welded.

Check whether the bearing seat and shaft diameter are worn. If the shaft is worn, generally make up welding and then turn round; if the bearing seat is worn, the separate bearing seat is generally replaced with new parts without repair; if the bearing seat and the side cover plate are integrated, make up welding of the bearing seat, so that the fit clearance meets the technical requirements.

4, gear wear

Gear wear, gear side clearance increases, will cause the two rotor position changes, so that the active rotor and the slave rotor hinge clearance between the hinge becomes smaller, the foliation gap increases, causing the two rotors to collide with each other, friction.

Solution: Check the tooth side clearance, replace the gear, use red Dan powder to check the contact area of the gear meshing parts. Check the tooth side clearance methods are playing the meter method, plug ruler method, pressure lead wire method. If the test results do not meet the requirements, the gear needs to be replaced.

5, rotor or shell deformation

If the rotor or shell is deformed, it will make the clearance between the outer diameter of the rotor and the shell too small, resulting in rotor friction and jamming.

Solution: Measure the clearance between the rotor and the casing with a plug ruler, and the deformation is small enough to be polished; if the deformation is large or the rotor and the casing are cracked, the rotor should be scrapped in time.

6, the rotor end face and side cover plate clearance is small

If the rotor and the side cover plate clearance is too small, there are debris squeezed into the rotor and the side cover plate; or axial positioning bearing wear, the axial runout of the rotor becomes larger, all resulting in friction between the rotor and the side cover plate, causing the rotor jams.

Solution: clean up the rotor end face and side cover plate, use the plug rule method to detect the axial clearance between the rotor end face and the casing, if the unilateral clearance is inappropriate, can be adjusted by adding or subtracting the bearing adjustment shims; if the total clearance is not appropriate, can be adjusted by adding or subtracting the side cover plate adjustment shims on the bonding surface, but the thickness of the shims is generally not more than 1mm.