Turbo Blower

-

10 YEARS WARRANTY

-

ENVIRONMENT FRIENDLY

-

DOWNLOAD PDF

- Product details

- Manufacturer Strength

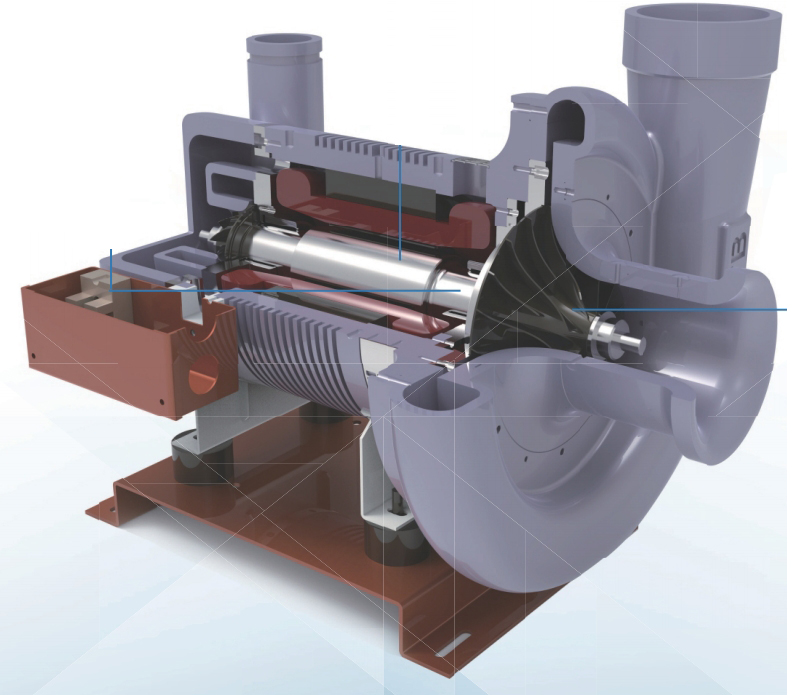

CORE TECHNOLOGIES

Completely independent intellectual property rights independent research and development and manufacturing.

1.AIRFOIL BEARING

- Stable performance

- Without wear

- No over-heating

- Oil-free

- No pollution to then environment

- Lifetime maintenance-free

2.HIGH SPEED PERMANENT MAGNET SYNCHRONOUS MOTOR

- Maximum speed can reach 400,000 rpm

- 100,000 trouble-free starts and stops;

- Motor efficiency can reach over 98%;

- Simple structure and small size;

- The motor is directly connected to the impeller,without power transmission loss

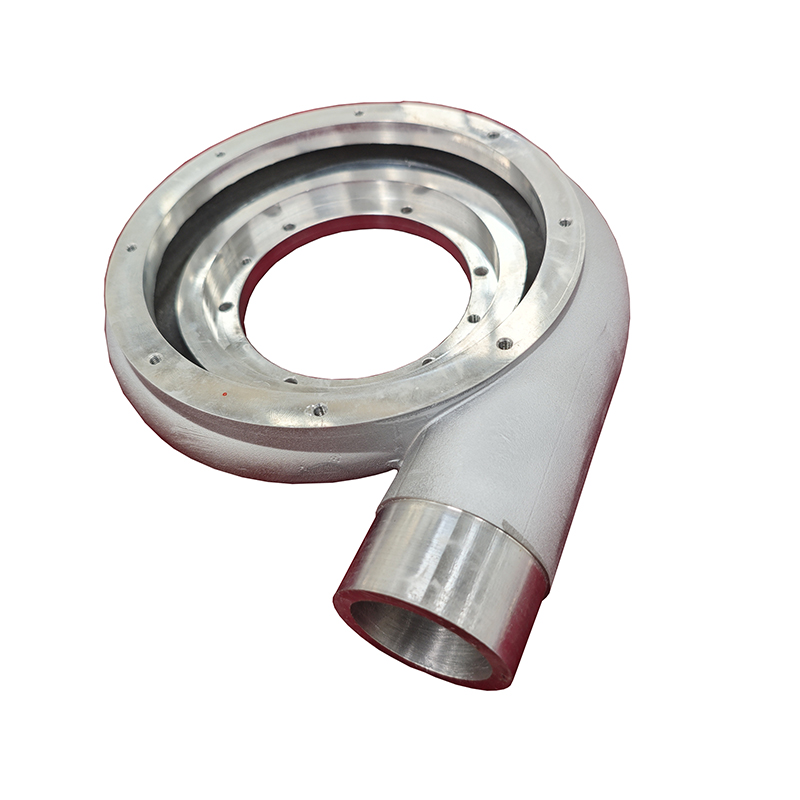

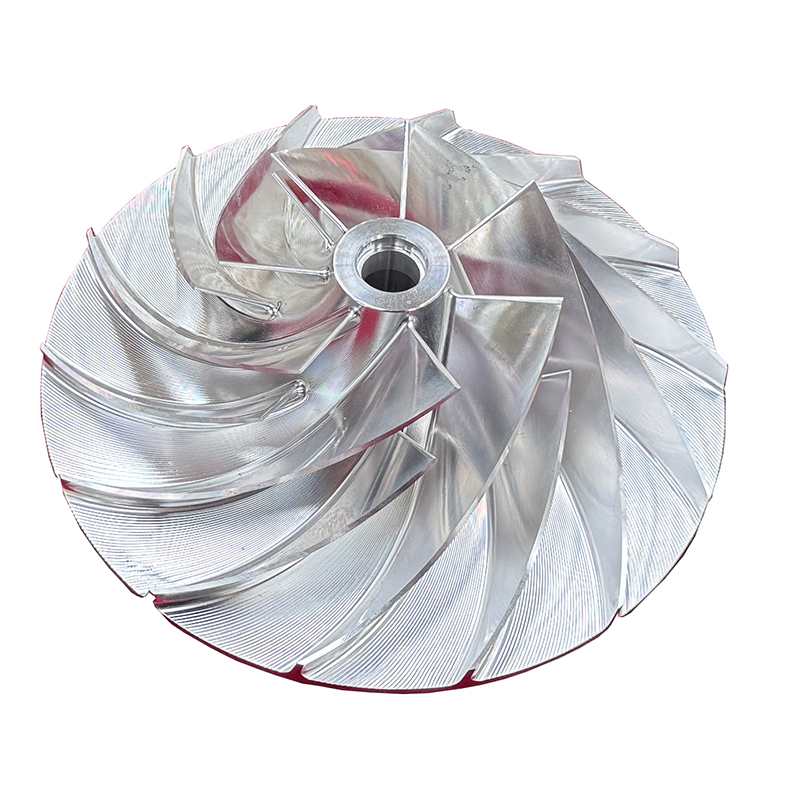

3.THREE-DIMENSIONAL CENTRIFUGAL IMPELLER

- Three-dimensional flow with backward-curved pneumatic design,

- high efficiency and wide working range.

- Five-axis manufacturing center, high-precision milling and forming

- Selected high-strength aviation alluminium material,

- with hard anodization on the surface, high strength,

- with good corrosion resistance.

4.HIGH SPEED VECTOR CONTROL INVERTER

- Equipped with a high-speed vector control inverter

- dedicated to permanent magnet synchronous motors,

- which can quickly adjust the high-speed rotation of

- the motor through frequency changes. The starting current is small;

- The frequency converter efficiency is greater than 97%;

- Speed control is precise

PRODUCT FEATURES

LONG LIFE LIFE : No friction, life span is more than 20 years.

SMART OVERALL DESIGN :Integrated design, the volume is only 1/3 of the traditional blower,Easy to install,no foundation required, just place it directly

EASY MAINTENANCE :Just change the filter regularly

ULTRA-HIGH EFFICIENCY:Integrated high-speed permanent magnetsynchronous motor,High-efficiency centrifugal impeller, air bearing,And adjust the blower operating status according to the load conditionUnder normal conditions, it can save 30%~50% energy than traditional blower.

CLOUD INTELLIGENT CONTROL:Users’ mobile terminals and PC terminals can remotely transmit all data for unified management and analysis.

OIL-FREE:Using advanced air bearings, there is no friction and no need for lubrication.

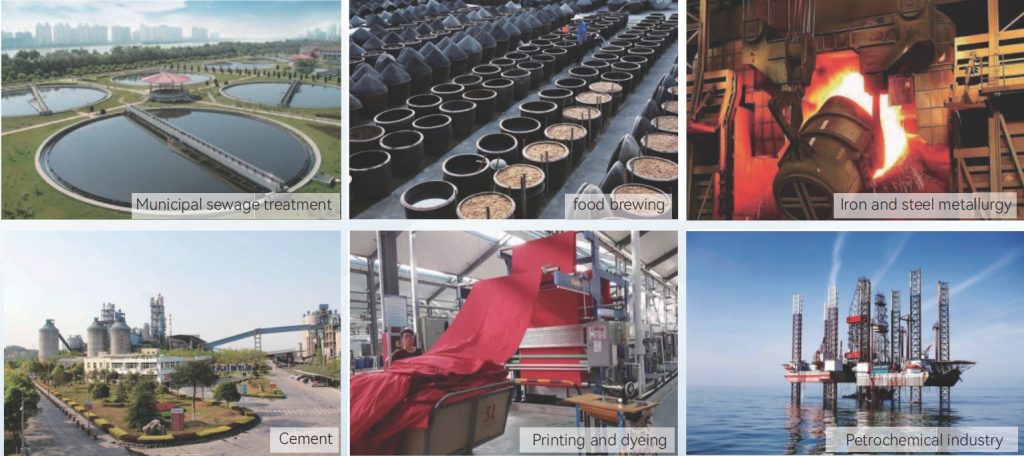

MARKET APPLICATION

Specifications

1.Rated flow measurement conditions: 101.325kPa, 20'℃ ,65%RH; 2.Noise test conditions: The test site is a place with no reflection

3.0utlet pipe flange pressure level: PN10, 4.For detailed indicators, please refer to theblower series product specifications. 5.For detailed specifications, please refer to the product specifications. |

||||

| Model | HGA2.2 | HGA3.7 | HGA5.5 | kPa |

| Airflow m³/min | 2.3 | 3.5 | 6 | 40 |

| Airflow m³/min | 一 | - | - | 60 |

| Airflow m³/min | - | - | - | 80 |

| kW | 2.2 | 3.7 | 5.5 | |

Overall dimension(mm):800X500X730(LxWxH) |

||||

Outlet diameter(mm):DN65 |

||||

| Model | HGA7.5 | HGA11 | HGA15 | kPa |

| Airflow m³/min | 8 | 11.5 | 16 | 40 |

| Airflow m³/min | 6 | 8.5 | 12 | 60 |

| Airflow m³/min | 一 | 6 | 10 | 80 |

| kW | 7.5 | 11 | 15 | |

Overall dimension(mm):1100X680X830(LxWxH) |

||||

Outlet diameter(mm):DN100 |

||||

| Model | HGA22 | HGA30 | HGA37 | kPa |

| Airflow m³/min | 29 | 38 | 48 | 40 |

| Airflow m³/min | 21 | 28 | 34 | 60 |

| Airflow m³/min | 15 | 22 | 26 | 80 |

| kW | 22 | 30 | 37 | |

Overall dimension(mm):1360X7b 50X1150(LxWxH) |

||||

Outlet diameter(mm):DN150 |

||||

| Model | HGA45 | HGA55 | kPa | |

| Airflow m³/min | 58 | 65 | 40 | |

| Airflow m³/min | 40 | 51 | 60 | |

| Airflow m³/min | 32 | 42 | 80 | |

| kW | 45 | 55 | ||

Overall dimension(mm):1590X750X1350(LxWxH) |

||||

Outlet diameter(mm):DN200 |

||||

| Model | HGA75 | HGA90 | kPa | |

| Airflow m³/min | 95 | 120 | 40 | |

| Airflow m³/min | 65 | 86 | 60 | |

| Airflow m³/min | 55 | 69 | 80 | |

| kW | 75 | 90 | ||

Overall dimension(mm):1550X750X1350(LxWxH) |

||||

Outlet diameter(mm):DN200 |

||||

| Model | HGA110 | HGA150 | kPa | |

| Airflow m³/min | 150 | 190 | 40 | |

| Airflow m³/min | 104 | 140 | 60 | |

| Airflow m³/min | 86 | 110 | 80 | |

| kW | 110 | 150 | ||

Overall dimension(mm):2000X950X1800(LxWxH) |

||||

Outlet diameter(mm):DN300 |

||||

| Model | HGA220 | HGA300 | kPa | |

| Airflow m³/min | 242 | 328 | 40 | |

| Airflow m³/min | 210 | 260 | 60 | |

| Airflow m³/min | 160 | 220 | 80 | |

| kW | 220 | 300 | ||

Overall dimension(mm):2900X1600X2810(LxWxH) |

||||

Outlet diameter(mm):DN400 |

||||

Applications

-

Quality Assurance

Our company uses simulated working condition experiments for each blower we produce, and each blower undergoes strict testing before it leaves the factory.

Learn More -

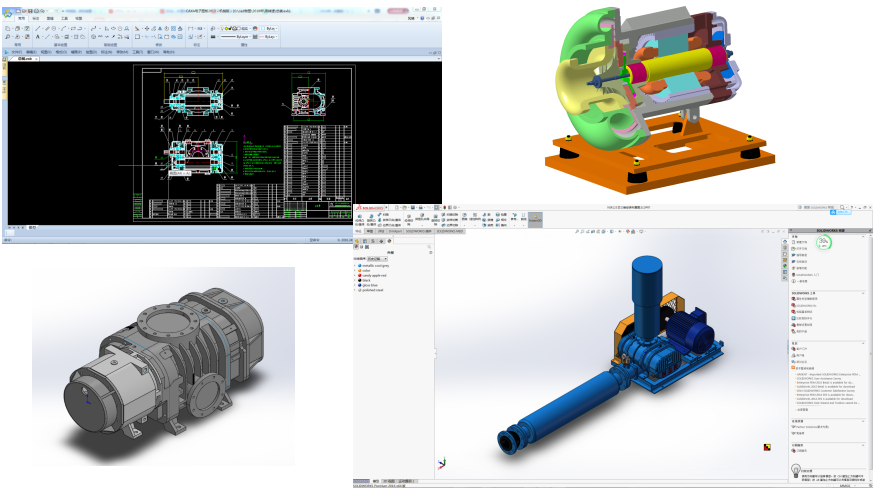

Intelligent Production

Roots blowers are equipped with advanced control systems for precise gas flow and pressure control

Learn More -

After-sales Service

Our sales outlets and after-sales service centers are located in many countries around the world...

Learn More

Any questions on our machines?

About Company

Teamup is a company founded in 2004 and has been dedicated to the independent development, manufacture, sales and service of blowers since the beginning. At present, the company’s Roots Blower Division has developed into a comprehensive blower manufacturer including five series and hundreds of models; the Multi-stage Centrifugal Division produces a wide range of multi-stage centrifugal blowers; in addition, the company also has the Screw Blower Division, Rotary Blower Division and Air Suspension Blower Division, all of which are in the leading position in the industry in terms of technical strength and production scale.

Teamup is able to produce more than 30,000 units/sets of blowers per year, and is in the leading position in the blower industry with its complete product range, excellent innovation capability, strong technical force, high processing precision and perfect after-sales service.

Our Advantages

Intelligent detection system for roots blowers

Our company adopts simulated working condition experiment for each blower produced, and each blower is strictly tested before leaving the factory.

Advanced processing technology

More than fifty sets of CNC machining machines, the processing strength in the domestic blower industry is second to none

Strict quality control

Established and improved the quality assurance of design, manufacturing, installation and service.

Focus on R&D

The whole process from R&D design to product delivery is controlled independently, which provides sufficient basis and reliable guarantee for the stability and durability of products.

Complete after-sales service system

Our sales outlets and after-sales service centers are located all over the country and surrounding countries. We strive to provide customers with better and faster service.

Need Any Blowers Solution?

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.

Contact Us