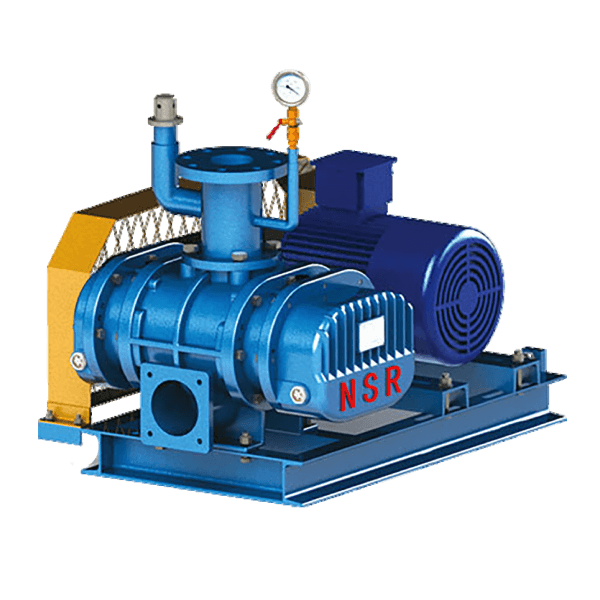

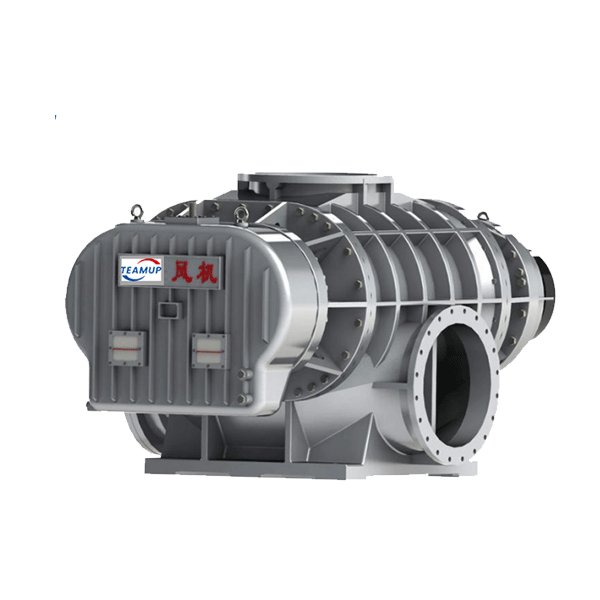

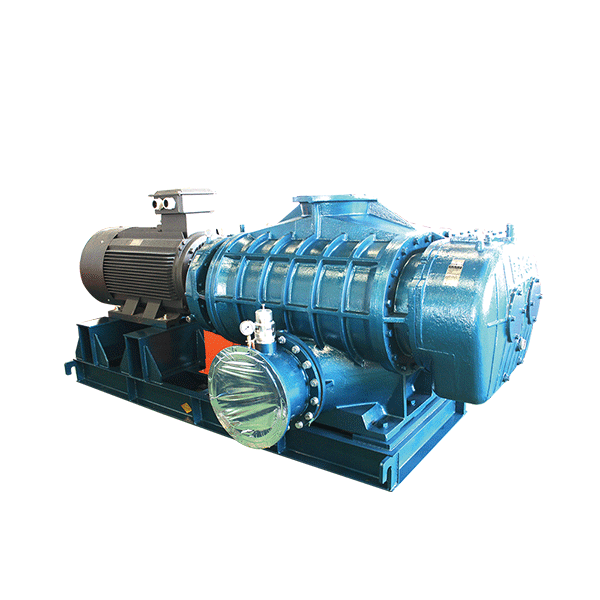

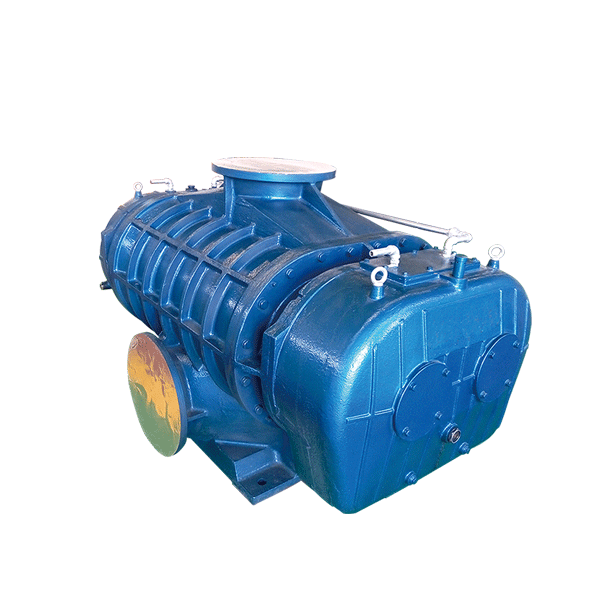

Twin lobe roots blower pump

- Caliber(mm):Φ250-Φ350mm

- Capacity(m³/min):60-220m³/min

- Pressure (kpa): -53.3~58.8kpa

- Caliber(mm):Φ350-Φ500mm

- Capacity(m³/min):160-450m³/min

- Pressure (kpa): -53.3~98kpa

-

10 YEARS WARRANTY

-

ENVIRONMENT FRIENDLY

-

DOWNLOAD PDF

- Product details

- Manufacturer Strength

Product Introduction

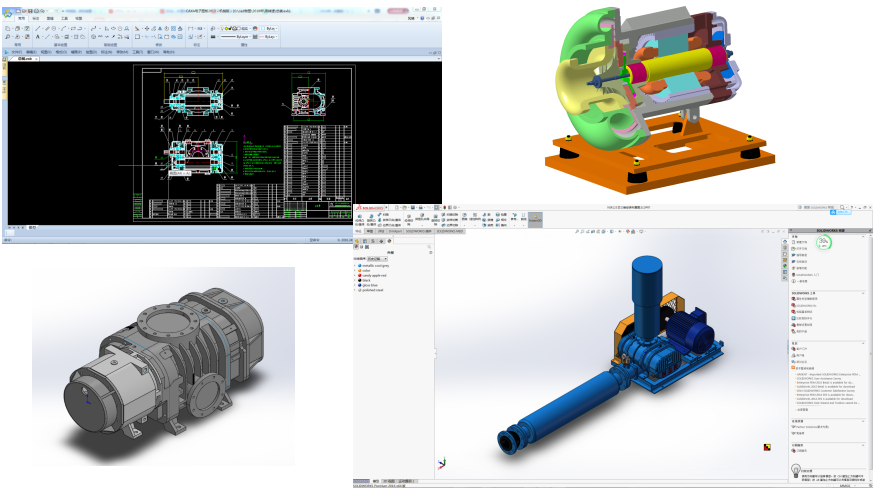

In the field of large-diameter 2 lobe roots blower pump, SNRR and RG models are a new type of high-efficiency and energy-saving units. This series of products have assembled the results of many years of aerodynamic research and developed a new type of impeller profile by using 3D simulation technology. Although the impeller under the new line is complicated to process, it is highly efficient and low noise. The unit is the world leader in high pressure and special gas transmission.

2 lobe roots blower pump specifications

This series of Roots blowers has many specifications, including positive pressure, negative pressure, dry type, wet type, single stage and double stage (see TN series for details). And according to the different mediums conveyed, there are various forms of seals: labyrinth type, rising ring type, packing type, mechanical seal type, etc.

This series of Roots blower units are widely used in electric power, petroleum, chemical industry, fertilizer, steel, smelting, oxygen production, cement, food, textile, paper, dust removal and back-blowing, aquaculture, sewage treatment, pneumatic conveying and other sectors.

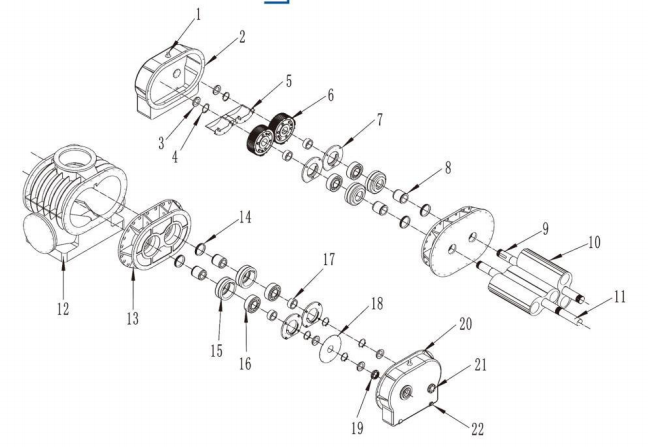

Two-lobe Roots blower construction diagram and material

| No. | Name | Material | Qty |

|---|---|---|---|

| 1 | Exhaust gas | 45 | 2 |

| 2 | Main oil tank | HT250 | 1 |

| 3 | Round nut | 35 | 5 |

| 4 | Round nut stop washer | Q235A | 5 |

| 5 | Oil spacer | Q235A | 1 |

| 6 | Gears | 35CrMo | 2 |

| 7 | Bearing gland | Q235A | 2 |

| 8 | Seal inner sleeve | Q235A | 4 |

| 9 | Slave shaft | 45 | 1 |

| 10 | Impeller | HT250 | 2 |

| 11 | Main shaft | 45 | 1 |

| 12 | Housing | HT250 | 1 |

| 13 | Wall plate | HT250 | 2 |

| 14 | Simmerring oil seal | Fluoroelastomer | 4 |

| 15 | Bearing seat | HT250 | 4 |

| 16 | Bearing | Bearing Steel | 4 |

| 17 | Shaft sleeve | 92354 | 4 |

| 18 | Oil throwing disc | Q235A | 1 |

| 19 | Simmerring Oil Seal | Fluoroelastomer | 3 |

| 20 | Secondary oil tank | HT250 | 1 |

| 21 | Oil marker | Plexiglass | 4 |

| 22 | Oil drain screw plug | 45 | 2 |

Recommended

Applications

-

Quality Assurance

Our company uses simulated working condition experiments for each blower we produce, and each blower undergoes strict testing before it leaves the factory.

Learn More -

Intelligent Production

Roots blowers are equipped with advanced control systems for precise gas flow and pressure control

Learn More -

After-sales Service

Our sales outlets and after-sales service centers are located in many countries around the world...

Learn More

Any questions on our machines?

About Company

Teamup is a company founded in 2004 and has been dedicated to the independent development, manufacture, sales and service of blowers since the beginning. At present, the company’s Roots Blower Division has developed into a comprehensive blower manufacturer including five series and hundreds of models; the Multi-stage Centrifugal Division produces a wide range of multi-stage centrifugal blowers; in addition, the company also has the Screw Blower Division, Rotary Blower Division and Air Suspension Blower Division, all of which are in the leading position in the industry in terms of technical strength and production scale.

Teamup is able to produce more than 30,000 units/sets of blowers per year, and is in the leading position in the blower industry with its complete product range, excellent innovation capability, strong technical force, high processing precision and perfect after-sales service.

Our Advantages

Intelligent detection system for roots blowers

Our company adopts simulated working condition experiment for each blower produced, and each blower is strictly tested before leaving the factory.

Advanced processing technology

More than fifty sets of CNC machining machines, the processing strength in the domestic blower industry is second to none

Strict quality control

Established and improved the quality assurance of design, manufacturing, installation and service.

Focus on R&D

The whole process from R&D design to product delivery is controlled independently, which provides sufficient basis and reliable guarantee for the stability and durability of products.

Complete after-sales service system

Our sales outlets and after-sales service centers are located all over the country and surrounding countries. We strive to provide customers with better and faster service.

Need Any Blowers Solution?

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.

Contact Us