MVR Screw/Roots Steam Compressors

-

10 YEARS WARRANTY

-

ENVIRONMENT FRIENDLY

-

DOWNLOAD PDF

- Product details

- Manufacturer Strength

Product Description

MVR Industrial Waste Water Treatment System is a high-efficiency and energy-saving waste water treatment system independently developed by our company, which applies the heat pump energy-saving technology in the evaporation and crystallization system, and through the steam compressor, the secondary steam formed by the evaporation system will be compressed, pressurized and warmed up and the compressed steam will be recycled as the heat source of the evaporator, so that the secondary steam generated by evaporation can be fully utilized to greatly save energy, and in addition to the start-up of the machine, only a small amount of steam is required to replenish the steam in the course of normal operation.

The skid mounted MVR system integrates and modularizes the wastewater treatment system and concentrates it in skids or containers. The skid mounted MVR system is especially suitable for decentralized, highly polluted, small water volume occasions due to its excellent mobility, and can be operated continuously without an operator by using a computer for complete control, and its high ratio and excellent reuse water quality can make the sewage greatly reduced, and the complete reuse of the wastewater can be realized if necessary.

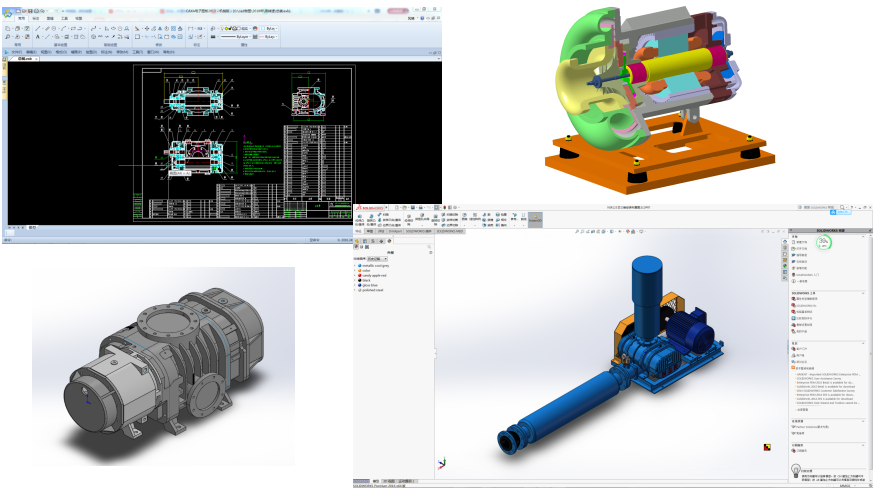

MVR Screw Steam Compressors

Specificities

- Maximum evaporation capacity 50 tons/hour

- Maximum pressure difference 10kg

- Maximum temperature difference 80 degrees

- Adopt permanent magnet frequency conversion PLC control

- Dry machine seal

- Zero leakage

- Oil-cooled mechanical seal

- Water-cooled mechanical seal

MVR Roots Steam Compressors

Specificities

- Maximum evaporation capacity 20 tons/hour

- Pressure 1kg

- Temperature difference 25 degrees

- Adopt permanent magnet frequency conversion PLC control

- Oil-cooled mechanical seal

- Water-cooled mechanical seal

- Zero leakage

Areas of Application

Paper

- High-content and high-viscosity wastewater concentration

- Black liquor evaporation system

Oil & Gas

- Zero-discharge system for petrochemical plants

- Zero Discharge Boiler Effluent

Metal smelting and mining

- Nickel, lithium, magnesium and zinc salt crystallization

- Alumina Waste Evaporation System

Salt production

- Sodium chloride evaporation and crystallization

- Sulfur rivulet ammonium evaporation and concentration

- Sodium sulfate evaporation and crystallization

Power

- FGD wastewater treatment system

Food and Pharmaceutical

- Evaporation and crystallization of various components

Chemical industry

- Crystallization of various chemical products

Fertilizer

- Potash evaporation and crystallization

- Ammonium sulfate evaporation crystallization

Hazardous waste

- Heavy metal wastewater evaporation crystallization

What is Mechanical Steam Recompression Technology (MVR) all about?

Specifications

Applications

-

Quality Assurance

Our company uses simulated working condition experiments for each blower we produce, and each blower undergoes strict testing before it leaves the factory.

Learn More -

Intelligent Production

Roots blowers are equipped with advanced control systems for precise gas flow and pressure control

Learn More -

After-sales Service

Our sales outlets and after-sales service centers are located in many countries around the world...

Learn More

Any questions on our machines?

About Company

Teamup is a company founded in 2004 and has been dedicated to the independent development, manufacture, sales and service of blowers since the beginning. At present, the company’s Roots Blower Division has developed into a comprehensive blower manufacturer including five series and hundreds of models; the Multi-stage Centrifugal Division produces a wide range of multi-stage centrifugal blowers; in addition, the company also has the Screw Blower Division, Rotary Blower Division and Air Suspension Blower Division, all of which are in the leading position in the industry in terms of technical strength and production scale.

Teamup is able to produce more than 30,000 units/sets of blowers per year, and is in the leading position in the blower industry with its complete product range, excellent innovation capability, strong technical force, high processing precision and perfect after-sales service.

Our Advantages

Intelligent detection system for roots blowers

Our company adopts simulated working condition experiment for each blower produced, and each blower is strictly tested before leaving the factory.

Advanced processing technology

More than fifty sets of CNC machining machines, the processing strength in the domestic blower industry is second to none

Strict quality control

Established and improved the quality assurance of design, manufacturing, installation and service.

Focus on R&D

The whole process from R&D design to product delivery is controlled independently, which provides sufficient basis and reliable guarantee for the stability and durability of products.

Complete after-sales service system

Our sales outlets and after-sales service centers are located all over the country and surrounding countries. We strive to provide customers with better and faster service.

Need Any Blowers Solution?

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.

Contact Us